Video Description

Product Description

Adjustable height articulating load shelf to support the bag during packaging (250mm max bag length)

Print directly on the next bag being fed out or print and apply a label, up to 4″ in width (optional)

Compact design takes up minimal footprint in the packaging area

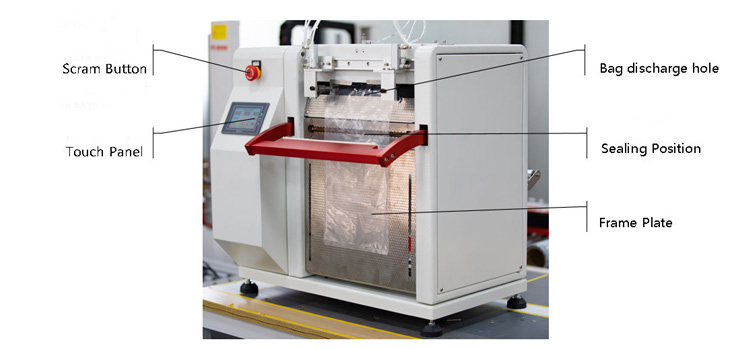

7” color touchscreen with user-friendly interface and clear prompts

Set-Up Benefits

Utilizes Rollbag pre-opened bags-on-a-roll for quick bag size changes and easy set-up

PLC with batch counters, packaging statistics, and login-in levels

Interface to infeed devices for a fully automatic packaging system

Nichrome wire heating element for fast start-

Operating Benefits

Operate with a footswitch, by hand, or in auto cycle mode up

Maintenance Benefits

Off the shelf modular components for easy replacement

Self-diagnostics ensure quick problem solving

Quick service access to all electrical components

Safety Benefits

Zero force seal bar closing virtually eliminates the chance of injury

Low power consumption design (1000 Watts)

CE compliant design for improved safety and troubleshooting

Detailed Images

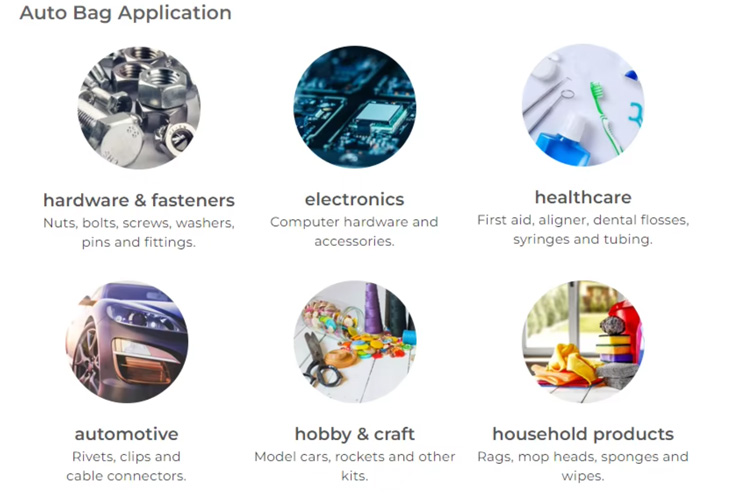

Product Applicant

Specifications:

Model | MS-DS02C |

Machine size LxWxH(mm) | L650*W750*H1100 |

Bag size(mm) | Min:L80*W50mm MAX:L500*W250mm |

Bag thickness | Single layer 0.04-0.1mm |

Packing speed | 8-25bags/min |

Mahchine weight | 120Kg |

Comsuption | 1.5Kw |

Power | 1PH 220V 50HZ |

Air supply | 0.4MPa 0.05m³/min |

Apply for film | PE pre opened bag film roll |

Lable Panel | L150*W100 |

Lable size | L:20-120mm W:20-100mm |

Part name | Brand |

Heating Element | DC power |

Heat sealing part | Nichrome wire |

Sensor | Fiber |

Cylinder | SMC/AirATC |

Sensor for detect bag | AI-controlled current sensor |

Motor | Leadshine Stepper Drive |

Bearing | HER |

Film roll support | Max film roll D250mm |

PLC | Mitsubishi |

Company profile

FAQ:

Q1: Are you factory or trading company?

A: We are both manufacturers and traders .We sell both our own products and Other associated equipment, all equipment is manufactured and tested under our strict acceptance standards.

Q2: Can you guarantee your quality?

A: Yes, we have a strict manufacturing and installation process and all equipment is tested for three days before leaving the factory.Pneumatic and electrical components are of well-known brands.

Q3: What should I do if we are not able to operate the machine when we receive it?

A: Operation manual and video demonstration sent along with the machine to give instructions. Besides,we provide on line video chat support . we have professional after-sale group to customer 's site to solve any problems.Major overseas sales team members have a certain technical background and can quickly understand customer needs and after-sales technical issues. Provide professional services and support to overseas customers.

Q4: How could I get the spares on machines?

A:We will send extra sets of easy broken spares and accessories like O ring belt etc. Non-artificial damaged spares will be sent freely during 1 year's warranty.

Contact:Elaine Chen

Phone:0086 13129570396

Whatsapp:0086 13129570396

E-mail:info@inautomachine.com

Add:Wangjin High Tech Industry Park,Qiaotou Town,Dongguan City,Guangdong Province,China